About Us

Discover Your Personal Style and the Confidence That Comes with It.

Vihana Export is the new player in the fast fashion production industry. Everyday our factory creates fashion apparels for leading retail brands of India. Our parent company Shah Motilal Sureshkumar has a premium legacy of more than 30 years in the industry.

Founded in 1979 with core knowledge of fabric textile. Within 2 years we are proud to work with leading brands like Reliance Retail Private Limited ,Vedic, and platform like Ajio.

With a strong team and a clear vision we are looking forward to enhance our experience in this field and our expertise in fast fashion apparel production.

Service for all

We Love To Help People Feel Great About How They Look.

VISION

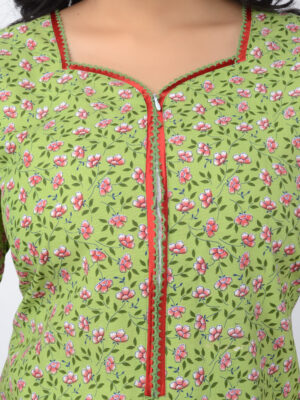

Vihana has evolved beyond kurtis and always believed in new challenges and experience. With an idea of cost effectiveness and quality at the same time Vihana has a vision to enter the western wear production line

and thrive as a one stop solution for all buyers.

MISSION

Our goal is where we brought everything to life. With a spirit of technology and re-invention, and with a mission of building the premium home and furnishing products, we have come a long way.

Our goal is to provide good quality product with 100% customer satisfaction.

Our Journey

1976

Shah Motilal came to Gujarat from Rajasthan and started as a fabric agent.

1981

Started their own shop as a dealer/distributor of Tata, Omkar, Chiripal, Aarvi over Maharashtra, Karnataka, and Goa

1985

Started shirting and trading with Motitex and Ramatex from Maharasthtra and Rajasthan.

1990

From Bhiwani and Malegaon, begun producing shirting sarees with grey finish.

2000

Till now, saree (navrai) and

plain shirting dye

2012

Pathik Bavarlal Jain began his business as a Kurti and dress

material trader

2013

Production started from Jetpur

2018

Garment Manufacturing Company in Ahmedabad, Production now only in Jetpur and Ahmedabad.

Infrastructure Facility

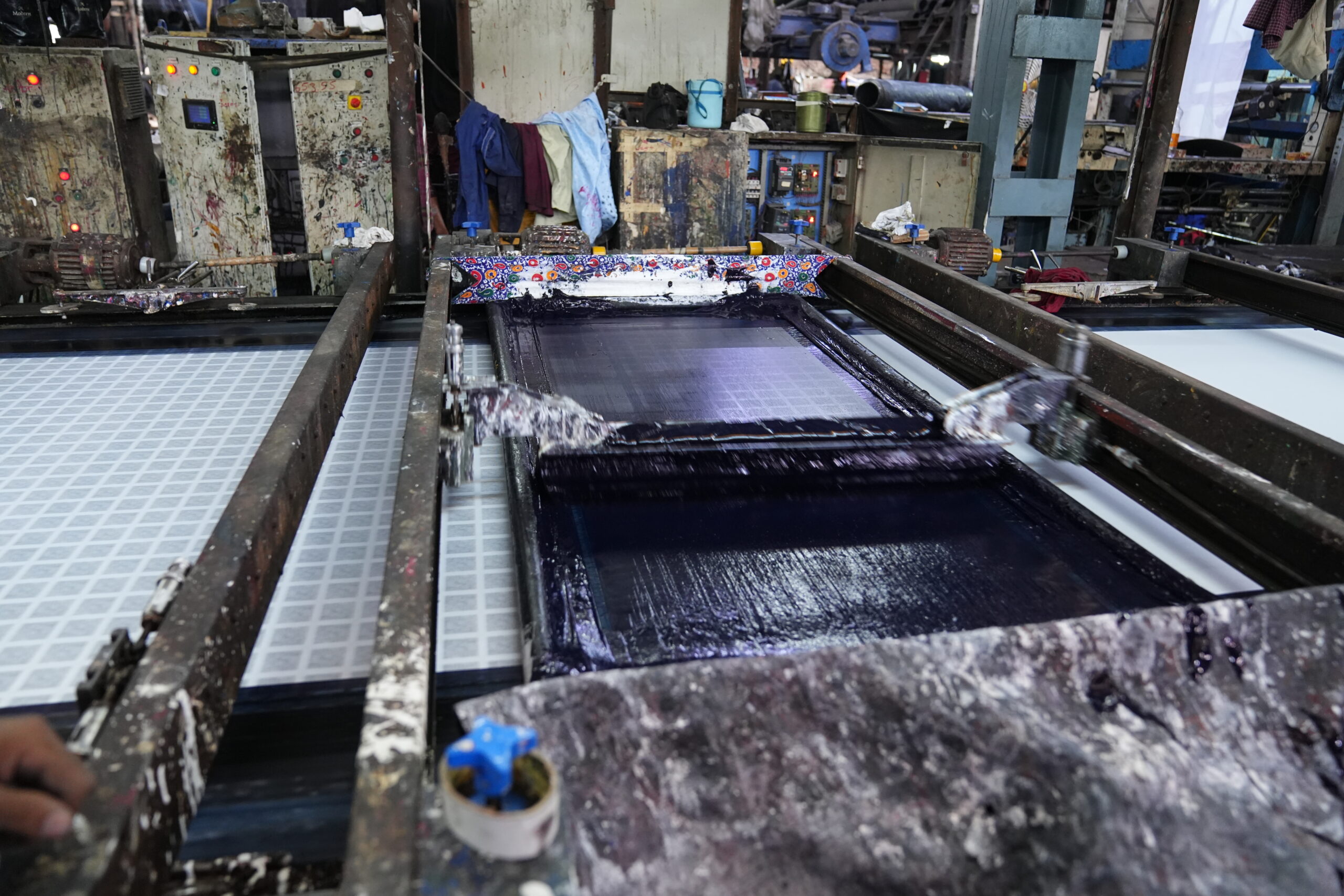

we have a complete infrastructure facility from Designing the garments to delivery, In- house production process includes design house , cutting embroidery, printing, sewing and finishing under one roof to ensure quality in every process and timely delivering.

Our state of the art production facilities of 150 sewing machines with monthly capacity of 200,000 fashion garments which includes both woven and knits .

rotary printing

Sewing

Placement printing

Dying

Finishing

Knitting

Cutting

Embroidery

Production & Capacity

We have 150 Machine Set Up with capacity of current 200,000 Pcs per Month But we are finically and technically ready to extend our capacity to 500+Machine and Monthly production of 600,000 Pcs based on demand. Currently we are manufacturing both Woven and Knits garments

in all the catagories.

Work Flow

You

Your Design Idea

Processing Idea

Our Team

Manufacturing

Your Final Approval

Product Development

Our Platform

Quality Check

Packing

Final Inspection

Dispatch

Order execution and Quality Control

Order are closely monitored from sampling to shipment with proper TNA which is shared with Buyers on regular basis.

Our Quality Monitoring System Pertaining To Production Has Four Stages Below

Pre Production Checking (PPC)

Initial Production Checking (IPC)

Inline Midline inspection

Final inspection

Our Products

Our Amazing Clients

Cutting-Edge Tech

For Stitching, We Have Brother, Juki, Kansai Stitching Machines And Steam Press Systems.

But What Makes Vihana Exports Truly excellent Are The People behind The Machines. The Entire Process Is

Monitored By A Group Of Experts Whose Experience In The Business Ensures That Our

Finished Garments Stand Out From The Competition

Our Commitment

Quality with on time delivery is a fundamental commitment we make to our customers to ensure we have detailed procedures in our QA department covering check from raw material to finished goods.

Sedex certification process in underway and the final certification will be in place by March-2023. Quest to excel and aim in partnerships that withstand the test of time and quality.

Focus on customer satisfaction and provide good working conditions to workers.

The company believes in providing fair and ethical working atmosphere